|

| Micro Kossel and Mini Kossel |

|

| Escher 3D Delta Calibration Wizard |

|

| Pronterface waiting to connect to a printer |

|

| Pronterface after Connecting to the Printer |

|

| Parameters for the Micro Kossel entered into the Delta Wizard |

Now it's time to use the piece of paper to actually measure the differences between the firmware's settings and reality. This is a fairly simple routine, first put the piece of paper on the print bed over the spot you want to measure. Then click the 'Home all' button, red arrow in the screenshot below, to zero the printer's coordinate system. Next, use the command line interface, green box/arrow in the screenshot below, and input something like 'G1 X0 Y0 Z 20' and click 'send' or press enter.

|

| Pronterface with key controls highlighted |

|

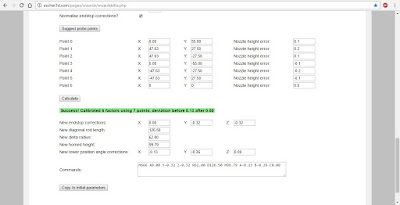

| Finished Calibration Wizard |

Congratulations, you've successfully calibrated a delta 3D printer, now it's time to start making things with it.

No comments:

Post a Comment